Will 3D Printing Replace Other Manufacturing Methods?

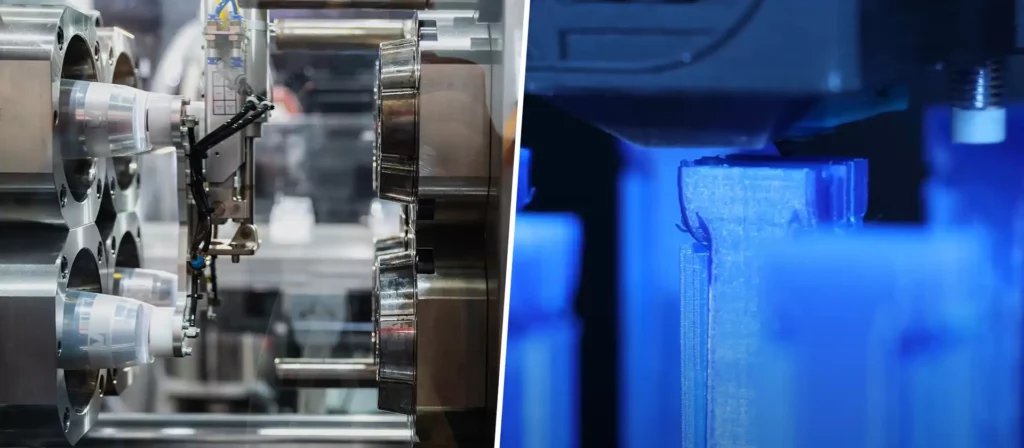

The world of manufacturing leaves no room for any mistakes, inefficacies, and suboptimal results. Manufacturers have streamlined their methods to a point where they can produce the products they want, as fast, cheap, and reliably as possible to stay ahead of the completion and to maximize profits. In this high-risk, high-reward environment of the manufacturing industry, it sometimes seems like there is no room for innovation. That’s why additive manufacturing as a concept captured the imagination of people from all verticals and become a staple in countless different industries while methods like injection molding and pressing still reign supreme in manufacturing. 3D printing offers has its strengths and weakness right now and its uses have not even come close to reaching its future potential, but as a production tool, can 3D printing replace other manufacturing methods?

Why 3D Printing Has the Potential to Takeover Manufacturing

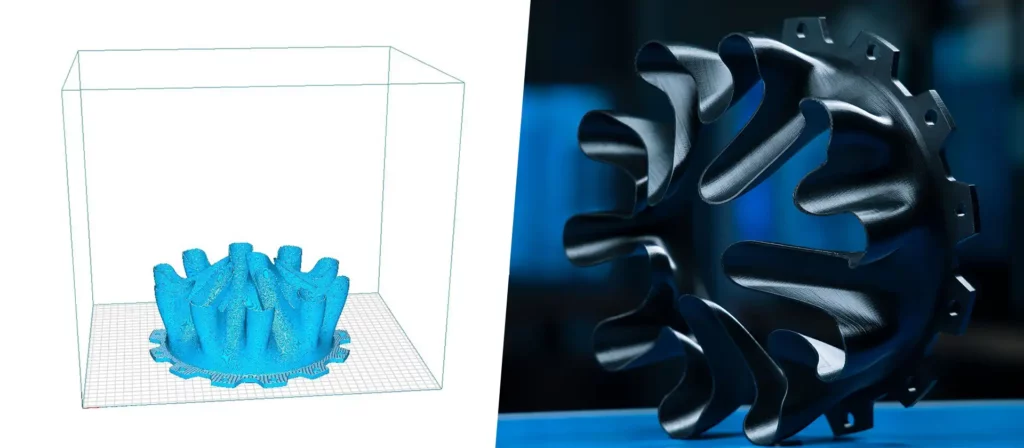

The reason why 3D printing has made such a splash in the public eye is simple. The idea of turning digital models into 3D printed parts really makes people think about the potential this concept has. It is a freedom that most manufacturers couldn’t even imagine of, considering how expensive and slow molding for a single part is. This flexibility and freedom additive manufacturing offers is perfect for certain industries that don’t need to mass produce products but need 3rd party help for things like model making and prototyping. Yes, the technology didn’t catch on in manufacturing as it did in these industries, but 3D printing still has some advantages that are inherent to this manufacturing method that makes it stand out among the others.

Flexibility

Being able to turn a digital file into a 3D object in a matter of hours will always be the selling point of 3D printing. It is such a big milestone for manufacturing that it might be considered a mini-industrial revolution on its own. Other manufacturing methods will always be limited by the molds, cutters, and other tools they require to start manufacturing while the 3D printer you buy is the tool. The setup process for a 3D print is the shortest among any other production method and this makes additive manufacturing arguably the most flexible manufacturing technology.

Lower Cost of Entry

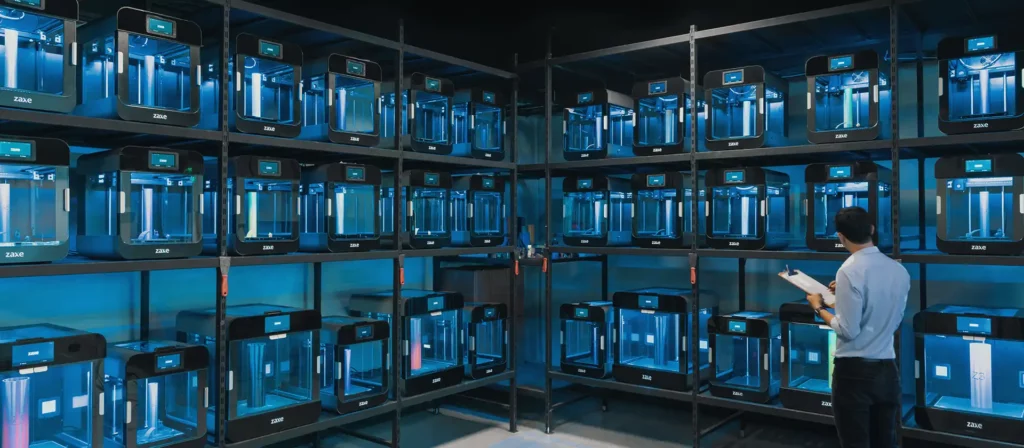

The other big advantage that 3D printing has over other manufacturing methods is the cost of entry. While an injection molding machine can, and often does, cost around six figures 3D printers are relatively affordable. For less than $500, you can be the proud owner of a desktop 3D printer, and if you need something better to use in a business environment, a professional-grade 3D printer will usually cost around $4000. A 3D printing production line is also much shorter and more scalable than other traditional manufacturing methods, making it better suited for businesses that have a smaller capital and people who expect a quicker return on their investments.

More on investing in 3D printers: 3D Printers as an Investment: How They Pay for Themselves

Potential for Advancements

While 3D printing technology is older than people think, it is still not that old. Traditional manufacturing methods had time to improve and optimize the production process which took them where they are right now. A lot of sources say additive manufacturing has been around since the 80s and there is some truth to that. But 3D printing as we know it today came to its own around the early 2000s. That’s why 3D printing still has the potential to take over the manufacturing industry. We are still witnessing the technology coming close to testing the limits of its capabilities and these fast developments give people the hope that 3D printing might be the future of manufacturing.

Shortcomings of 3D Printing

Like any other manufacturing method, 3D printing has its pros and cons. It does come with a lot of benefits as we mentioned above, but still, additive manufacturing’s shortcomings are the thing that keeps the technology from taking over all manufacturing.

The most important thing would be the print times. Yes, when it comes to manufacturing a brand new design, you would be hard-pressed to find a faster production method. But traditional manufacturing methods like injection molding still blow 3D printing out of the water when it comes to mass production of a single product. 3D printing closes this gap by offering scalability through a higher number of devices, but it is still not enough for some.

The other thing would be the layer lines that come with FFF / FDM 3D printing. These lines are a weak point for 3D printing both for performance and aesthetics as they mark the weakest points physically and tend to make the print surface less attractive. Luckily, there are ways to make the lines less noticeable with post-processing and decrease the negative performance effects of the layer lines through some slicer adjustments.

To get smooth finishes for your prints through post-processing, read: A Guide to Post-Processing for 3D Printing

There are other issues like limited printing volumes and a higher level of acceptable inaccuracy compared to some of the other manufacturing methods, but as long as the first two issues are resolved, we think the other problems will be trivial.

Possible Future Developments in 3D Printing

The place that 3D printing hold in the manufacturing industry as a whole will be determined by the developments that will come in the future, both in technology and culture. Developments like multi-purpose AI integration, a surge in home use, better filaments and fully automated 3D printing farms can and, in our opinion, will carry additive manufacturing to the next level. It’s only a matter of time before the technology catches up with the full potential of 3D printing and provides us with the 3D printing experience we desire.

Read more: Developments in 3D Printing That Could Change the Industry

Improvements on the current capabilities of the devices like speed, quality, and precision will also help get the manufacturers on the additive manufacturing side.

Will 3D Printing Replace Other Manufacturing Methods?

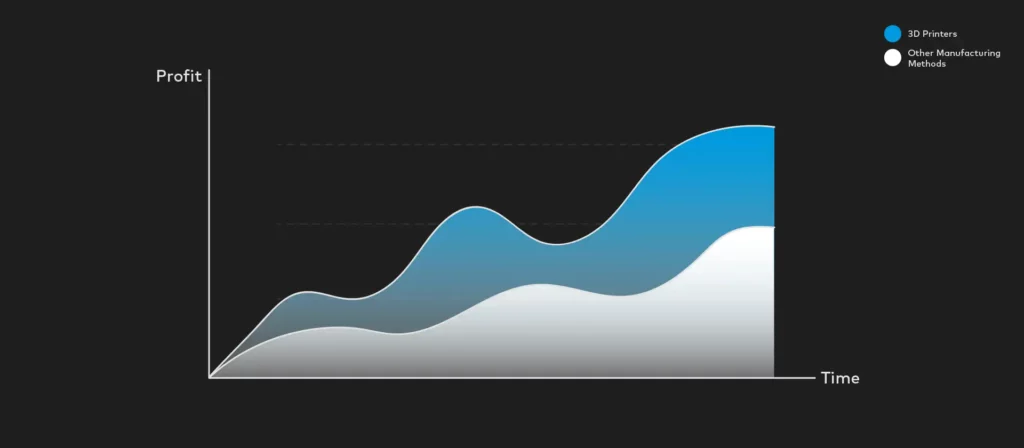

As it stands now, 3D printing is already in use in many different verticals and its potential for different purposes is just getting discovered. Will it ever replace the other manufacturing methods? If the answer to that question was a clear “Yes”, the landscape of investment in the 3D printing world would be much different right now.

While there are countless investors and passionate manufacturers that believe in the technology religiously, there is still a little skepticism when it comes to the possibility of 3D printing taking over other manufacturing methods. Only when 3D printing surpasses every other manufacturing method in most aspects, we would see it dominating the manufacturing industry. But the chances of that happening are very slim in the near future.

There is no doubt that 3D printing will play a bigger part in the future of manufacturing than it does now thanks to future developments, new 3D printing techniques, and increasing cultural relevance. But even when that happens, we think 3D printing will co-exist with other manufacturing methods as its own, unique thing and serve specific purposes in a much much higher capacity.