The Strongest 3D Printer Filaments on the Market

Strength is a much sought-after property for a 3D-printed item. It will dictate the durability and longevity of the printed end-use products and is directly correlated with the performance of the parts. Additive manufacturing is now being used in more fields than it ever did and as different industries start producing parts for heavy-duty purposes, the need for stronger and more durable filaments is at an all-time high. Which begs the questing “If you need a filament to print stronger end-use products, what is the strongest filament?”

What is the Strongest 3D Printer Filament?

There is no single “strongest filament”. The definition of strength or durability may change depending on a number of factors. What will be the working conditions of the printed part? Do you want longevity, elasticity, or UV resistance? There is more than one factor when defining strength. There are still a couple of filaments that undoubtedly outperform most of the other filaments on the market when it comes to different feats like tensile strength, tear resistance, impact strength, and flexural strength.

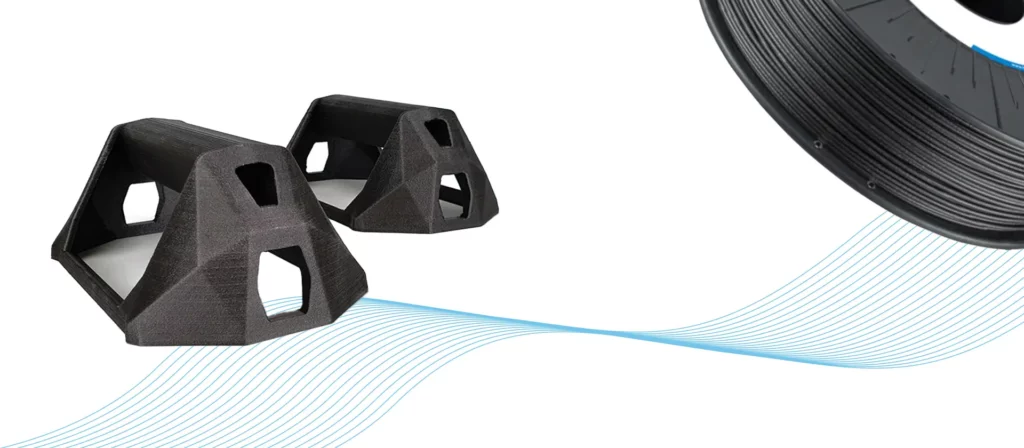

Polycarbonate

Polycarbonate, often called PC, is a high-performance heavy-duty filament that is widely used for engineering purposes. It has very impressive overall physical qualities that make it a go-to choice for rough environments. It performs well under extreme heat, is flexible enough to not be brittle, and absorbs impact well. It can be printed with consumer-level 3D printers which makes it undoubtedly one of the most available options when it comes to the strongest 3D printer filaments.

But PC has one shortcoming that makes it unappealing to some 3D printer users and it is the fact that it is so hard to print with. It requires a very high extruder temperature to print and when you print with it, it is prone to warping and oozing. It also has a short shelf life given the fact that it tends to absorb moisture in the air quickly.

If you want to improve the shelf life of your filaments: How to S tore Your 3D Printer Filaments Properly

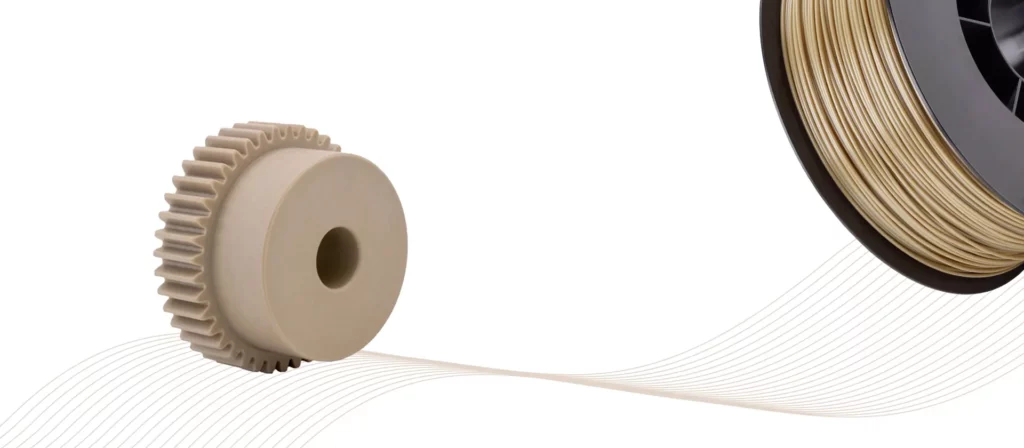

Nylon

Polyamide is another consumer-level filament that outperforms all the other popular filaments like ABS, PLA, and PETG when it comes to feats of strength. Nylon has a couple of advantages over PC like being more affordable, easy to print with, and flexible. It is durable, can perform in high temperatures, has impressive longevity, and users can get pretty smooth surfaces with it. Overall, nylon has pretty good price performance and can be a reliable alternative to PC.

While Nylon is one of the strongest 3D printer filaments, it still has some weak points. Just like PC, it absorbs the humidity in the air very quickly, decreasing its shelf life significantly and preventing it from being effective in outdoor use. It can also experience warping when cooling down so you will need to be a little bit more careful when printing with it to maintain dimensional stability.

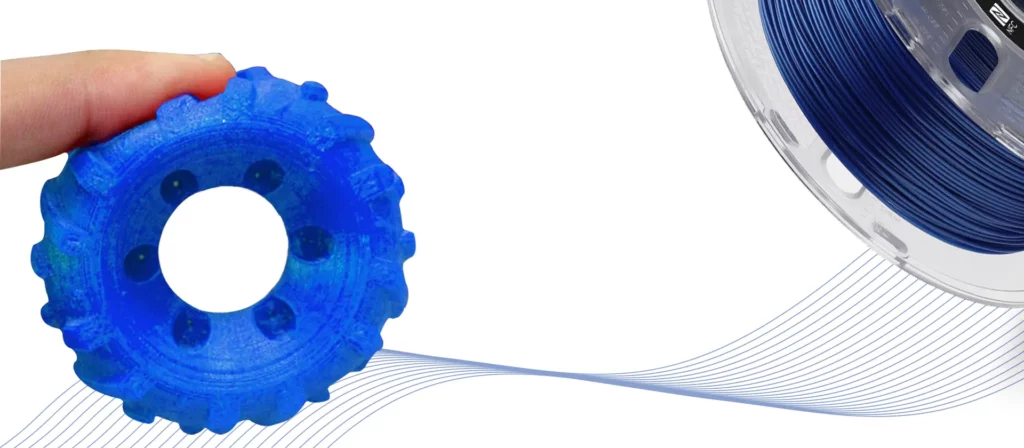

TPU / Flexible

TPU is often called Flexible Filament or FLEX due to its defining characteristic. It is undoubtedly one of the most elastic filaments on the market and a go-to choice for parts that require impact absorption and tear resistance. It also has a reasonably low melting point which means it can be used with most 3D printers on the market. You will need to be very precise with your 3D printer settings to get good results with TPU so the filament is only recommended for experienced 3D printer users.

Among many impressive properties, TPU has some that leave much to be desired. Firstly, it is considerably harder to print with than most other filaments. It oozes, you can’t print bridges and overhangs properly with it, and tends to cause stringing. But it is still one of the filaments that will give you the most flexibility.

PEEK

Polyether ether ketone, also known as PEEK, is another high-performance engineering filament that has some of the most physical properties among all the other plastics used in 3D printing. PEEK has very impressive thermal resistance, is not susceptible to wear and tear, can compete with a lot of metals durability-wise, and can do all these while being pretty light. It is in use in a variety of fields like medicine, engineering, and aerospace and the demand for PEEK is gradually growing because it’s no doubt, one of the strongest 3D printer filaments out there.

All these pros might make PEEK sound too good to be true but it also comes with a couple of cons. A spool of this filament will set you back a couple of hundred dollars so it is not the most budget-friendly filament. PEEK also has a melting temperature of 345°C so most 3D printers on the consumer level will not be able to print with this filament. You will likely need an industrial 3D printer which is quite expensive. To summarize, PEEK is an amazing material with a lot of uses but it will also be a big investment for people who want to use it.

To learn more about filaments like PEEK: A Guide to Industrial Filaments

Composite Materials

But you are not limited to one material in its pure form when you are choosing filaments. Actually, materials that are used in making filament usually synergize and mix with each other quite well. When you mix two materials together, you have the potential to get the best of both words. One filament can enhance the weak properties of the other, while they enhance each other’s strong sides. So let’s say you have PC on one hand and ABS on the other. Mixing these would create a material with PC’s heat resistance and ABS’s post-probability and ductility.

One of the only downsides is composite materials are often more expensive when they are in their pure form. The other thing is consistency. Companies that make the filaments change formulas and the split between two different filaments. So, one spool of PC-ABS you bought from one company probably won’t be the same as the one you bought from another.

Final Thoughts

Thanks to the many filament options that 3D printing offers, there is no shortage of strong material to use in your prints. The strongest 3D filament might be a topic of discussion because, as we have already said, there are different types of strength but one of these five filament types should be enough strength for most people. Depending on the purpose of the filament, there might be a better option for you. But except for very specific circumstances, one of these filaments will give you the best performance money can buy.