A Guide to Industrial Filaments

The power of additive manufacturing is getting discovered by new verticals every day and more and more industries are starting to use 3D printers to add flexibility to their production line. With these discoveries comes a demand for filaments that have different properties. Every customer’s needs are different and every part in a production line has a different purpose. Verticals like the automotive industry, engineers, aerospace, and engineering have an ever-rising interest in different materials that perform better than standard filaments like ABS and PLA as the performance requirement in these fields is much higher. That is why we now have an endless selection of filaments for all industries.

Best Industrial Filaments

The term “industrial” gets thrown around with no single meaning when it comes to 3D printing. You can find filaments and 3D printers with the “industrial” label on them but might not have an idea of what that means. When a filament is labeled industrial, it usually means that it can be used in extremely hot environments and can produce highly durable products. Some of these filaments are;

PEEK

PEEK, which stands for PolyEtherEtherKetone, is a high-performance plastic that is often used in heavy-duty industrial environments. Its mechanical, thermal, and chemical resistance and durability puts the filament leagues above similar plastic materials. While the price tag for the filament is considerably higher than the other materials that can be used for the same purpose, the performance and the longevity that PEEK offers more than makes up for it.

- 375°C-410°C printing temperature

- Surprisingly light

- Highly resilient

PEKK

Similar to PEEK in both name and physical properties, PEKK is another high-performance material that can be used for industrial purposes. Just like PEEK, it offers very impressive resistance against mechanical tension, heat, and chemicals and can even be considered in replacing some metals like steel thanks to its rigidity and durability. It is slightly more expensive than PEEK but PEKK comes with the benefit of being easier to print with.

- 345°C-375°C printing temperature

- Easier to print with than similar materials

- Versatile

PA

PA is known for its ability to blend very well with other filaments to improve its overall properties. While it harmonizes with other filaments extremely efficiently, PA in its purest state is still a workhorse of a filament. The shock absorption and flexibility capabilities of PA and the flexibility it has to offer in its pure form makes it suitable for heavy-duty spare parts.

- 225°C-265°C printing temperature

- Relatively flexible

- Longevity

PA-CF

PA-CF is the unique mix of polyamide and carbon fiber and is a popular choice among engineers due to the impressive properties it offers for industry-specific purposes. One of the biggest benefits of this industrial filament is its ability to print with little to no warping which makes it very suitable for prints that require high precision and tolerance. The filament provides a good level of tensility thanks to the carbon fiber infusion that adds a component of heat resistance and durability to the material.

- 260°C-280° C printing temperature

- Highly tensile

- Heat resistant

PA-GF

PA-GF is made by blending polyamide and glass fiber together to make a material that is suitable for functioning prototypes and high rigidity parts. Polyamide already shines in these aspects but the added glass fiber gives the filament more heat resistance. It is stiff, dense, and provides less wear and tear than most other filaments which makes it suitable even for some sporting goods.

- 280°C-290°C printing temperature

- Low wear and tear

- Isotropic behavior

PP

While most of the filaments we have listed here are renowned for their stiffness, PP is more of a flexible alternative. It is used to print parts that are fatigue resistant and it is genuinely hard to brake these part as they are quite indestructable. This makes PP great to print parts that will be under mechanical stress for a long time like hinges. When printed correctly, you can achieve visually appealing, smooth finishes on your prints with PP.

- 240°C-260°C printing temperature

- Flexible and unbreakable

- Smooth finishes

ASA

ASA, also known as Acrylonitrile Styrene Acrylate, is a synthetic thermoplastic that is very easy to print with compared to other filaments on this post. Being UV and weather resistant makes ASA applicable in outdoor use. Different industries take advantage of these properties by using ASA to manufacture automotive and marine equipment parts. It is also much less expensive than most of the other filaments on this list, so it is suitable for mass-producing end-use products.

- 240°C-250°C printing temperature

- High UV resistance

- Low warping

PEI / ULTEM

Like most other filaments that can be categorized as “industrial”, polyetherimide is another material that is renowned for its thermal and mechanical resistance. What makes PEI so special is thought is the ability to conduct heat effectively, which makes it stand out among other industrial filaments. It is actually the material that a lot of 3D printer companies, including Zaxe, make their print sheets from.

- 350°C-380°C printing temperature

- Thermal conductivity

- Good dielectric strength

PET-CF 15

PET-CF15 is a stiff material that provides amazing dimensional stability results in your print consistently and is known to be able to print parts with impressive longevity for the price tag. It absorbs little to no moister, making it perform great in high humidity and moist environments. It is also relatively affordable compared to some of the other filaments on this list, which makes it perfect for prototyping a variety of engineering parts without breaking the bank.

- 245°C-265°C printing temperature

- Low abrasion

- Pretty easy to print with

ABS Kevlar

If you used a 3D printer before you will probably be already familiar with ABS. The added aramid fibers give the standard ABS a little bit more stability and lightness to make an already impressive material even better, especially as an industrial filament. Compared to just basic ABS, ABS Kevlar experiences little to no warpage during the printing process and provides better dimensional accuracy which makes it much more suitable for end-use parts.

- 250°C-270°C printing temperature

- Smooth Finishes

- Low shrinkage

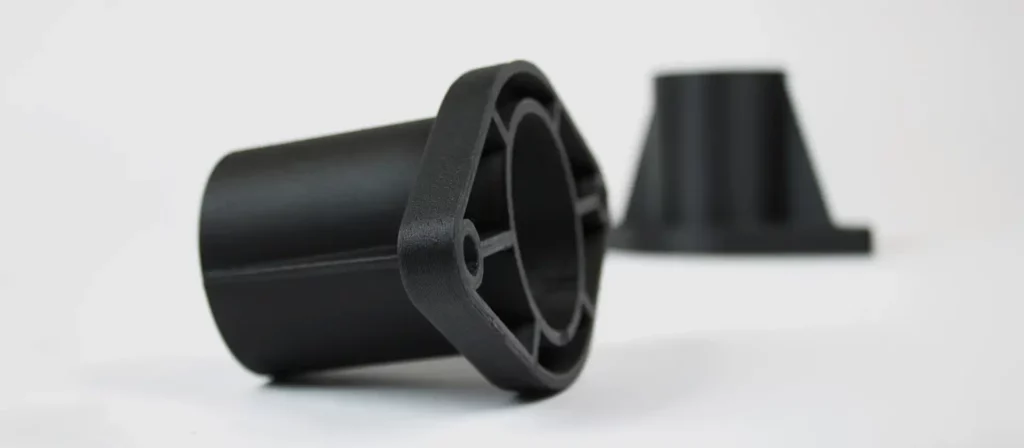

PC-ABS

Another ABS mix, PC-ABS utilizes polycarbonate’s superior heat resistance to turn pure ABS into an industrial filament. When printing, it behaves like regular ABS but performs much better in high-intensity work environments. You probably come into contact with a lot of PC-ABS as it is regularly used in automotive parts and consumer electronics due to its budget-friendly price point and impressive physical properties.

- 260°C-290°C printing temperature

- Affordable

- Easy to print with

If you are looking to learn more about different filaments: FILAMENTS 101

The information we have provided here will be a good intro to the world of industrial filaments. But there are countless industrial filament variations out there and even more blended materials that mix two different filaments to get the best of both worlds. Depending on the field you are going to use them and the specific properties you need, you might do more research and find the perfect filament.