How to Make PLA Stronger: Annealing 3D Prints

PLA is one of the, if not the, most popular filaments used in FDM 3D printing. The popularity of the material is no coincidence. It is exceptionally easy to print with, very budget-friendly, and sustainable as it is mostly derived from corn starch. PLA also has a pretty smooth finish, making it more appealing to the eye than most other filaments.

Thanks to its many positive attributes, PLA is consistently a best-selling filament that is mostly used for model making, prototyping, and some DIY home applications. One shortcoming of PLA that is a deal breaker for engineers and manufacturers is the fact that the material is pretty weak. But is there a way to fix this issue?

How Strong is PLA?

Among all the thermoplastics that are used in 3D printing, PLA is widely considered to be one of the weaker ones. It doesn’t perform well under mechanical stress, has pretty low impact resistance, and is susceptible to wear and tear. This makes PLA not suitable for parts that require high performance.

Beyond stress and impact resistance, PLA is not able to perform well under warmth, let alone heat. The material’s low melting point, which is a big selling point considering you can print using it with pretty much every 3D printer on the market, also hinders the possibility of it being used under heat.

There is a stronger alternative to standard PLA, often called PLA+. But, it is a slightly more costly material and is often not preferred by people who like the low price point of standard PLA. Additionally, PLA+ still doesn’t perform as well as some of the other popular filaments like ABS or PET-G.

If you need a strong filament, read: The Strongest 3D Printer Filaments on the Market

Making PLA Stronger with the Baking Method

While PLA is a relatively weak material, there are ways to make it stronger. Annealing has been a reliable method of making metal and glass more durable for hundreds of years. By heating a part beyond its recrystallization temperature, then allowing it to cool down slowly, people have been making materials stronger and increasing their ductility.

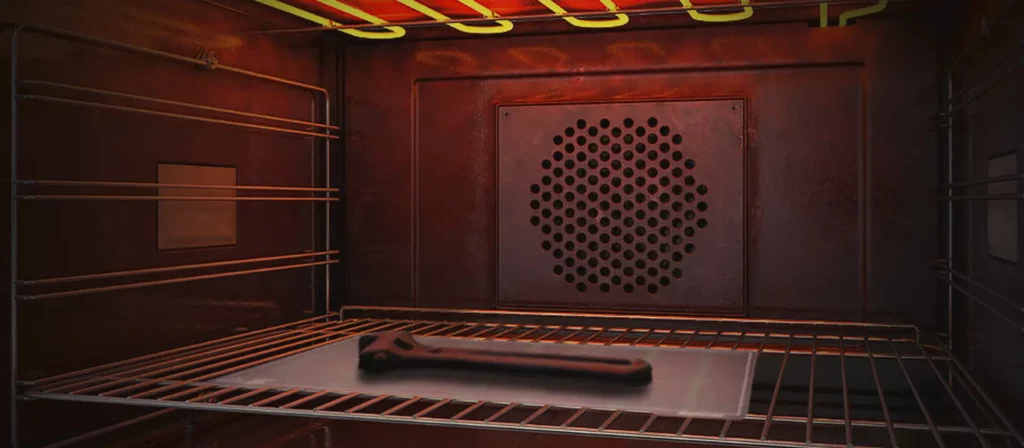

Luckily, PLA’s low melting point makes it possible to use the same annealing method on 3D printed parts. You can easily throw your PLA items in a standard kitchen oven and make the part considerably stronger. Annealing also helps with one of FDM 3D printing’s biggest weaknesses, which is the layer lines.

Normally annealing makes metal and glass stronger because it removes residual stress inside the material and prevents cracks from forming. While annealing does something similar for PLA, one of the main reasons why it makes PLA stronger is the fact that it improves adhesion between layers. Normally, these lines are accepted to be a weak point for FDM 3D printed parts as they are by far the most likely breaking point. But annealing helps parts that were printed using PLA to melt slightly and then cool off with better layer adhesion.

If you are still looking to make your printed parts stronger: How to Make 3D Printed Parts More Durable and Stronger

How to Anneal PLA 3D Prints

The process is extremely simple. All you need is an oven and a baking sheet to put your printed part on. If you have both of these items, we are good to go. Firstly, you will need to place the printed part you want to anneal on a baking sheet. Then you will have to preheat your oven. The temperature should be set to somewhere around 75-125 C to get your printed part to the optimal temperature. It usually takes 45 to 60 minutes for the part to get to the desired temperature.

After that, you can turn your oven off and wait for the part to cool down in the oven until it gets to room temperature. And that’s pretty much it. Your 3D printed part is now more durable, harder and its ductility has increased.

Final Thoughts

Is annealing PLA even worth it when you think about it? We would say it is in some cases. The method comes with a couple of shortcomings. The printed part will shrink and warp, ruining the part’s dimensional accuracy. And the end product still won’t be as strong as a part you print with a filament like ABS. But annealing PLA parts can be useful.

If PLA is the only filament you have at hand, or your 3D printer’s hotend can’t go up to higher temperatures, this method can make your 3D prints strong enough to be reliable for things like DIY home tools. If the dimensional accuracy of the part is not that crucial, annealing can make your prints strong enough to last longer for home use.

Annealing won’t make PLA an industrial filament. But it genuinely makes a material that is seen as one of the weaker filaments a reliable material for DIY tools. And if ever find yourself in need of a stronger filament while all you have at hand is a spool of PLA, it can help make your prints more durable.