Picking a 3D Printer Nozzle: Things to Consider

The nozzle is such an integral part of 3D printing that the choice you will make while buying them will directly affect so many aspects of your prints. From detail to printing speeds, your nozzle is a big part of your 3D printer’s performance. So you can’t leave your nozzle choices to luck.

But with so many types of nozzle out there, choosing one can be a little overwhelming. Different materials, diameters, and shapes all come with their pros and cons. Having a good idea of how different properties will affect your 3D prints is a must if you want to buy the right one.

Nozzle Materials

The material that the 3D printer nozzle you should pick will depend mostly on the filaments you want to use. If you are going to print with something simple like PLA, most nozzles on the market will perform decently. But if you want to 3D print using more industrial filaments, you are going to need a material that can handle a little heat.

Brass

If you bought a 3D printer without knowing much about these devices, chances are your 3D printer came with a brass nozzle. It is the most popular, budget-friendly, and reliable nozzle you can buy on the market and you can buy them in bulk to make them even more affordable.

Brass is so popular in making 3D printer nozzles because of its impressive heat-conducting properties and price performance. A brass nozzle will help you keep the temperature of the nozzle consistent with that of the hotend. This makes for a smoother 3D printing experience with most of the basic filaments you can find on the market.

Keep in mind that 3D printing food-safe products with a brass nozzle is not recommended as these nozzles are known to contaminate the printed part with led molecules, which could be detrimental to human health when consumed.

Before you start 3D printing food-safe parts, read: Food-Safe 3D Printing

Steel

If you need a more durable 3D printer nozzle to use some of the more industrial filament types that have a considerably higher melting point than other materials, steel will get the job done. While brass is usually limited to a maximum temperature of 300° C, steel 3D printer nozzle variants can go as high as 500° C.

They have a higher price point than brass nozzles but come with the advantage of being able to print with pretty much whatever filament type you want. There are two main choices of steel 3D printer nozzles on the market. Stainless steel is a good choice for people who want a trouble-free 3D printing experience without the risk of clogging and hardened steel is perfect for 3D printing with abrasive materials.

Specialty Nozzles

There are also a couple of very high-end specialty nozzles that are not used by the wide majority of the 3D printing point, mostly due to their price tags. There are assembled nozzles made from several different materials and can print with engineering materials like PEEK or Ultem. There are also nozzles like E3D’s X Nozzle which are technically made of steel but use a specialized alloy of tool steel to give superior performance when 3D printing with abrasive filaments.

Finally, there are extremely high-end nozzles like ruby nozzles that offer a lifetime of service. They can reach high temperatures with no trouble and provide low abrasion, good thermal conductivity, and durability. While they sound amazing at first, it is hard to justify a $100 price point when it comes to a 3D printer nozzle.

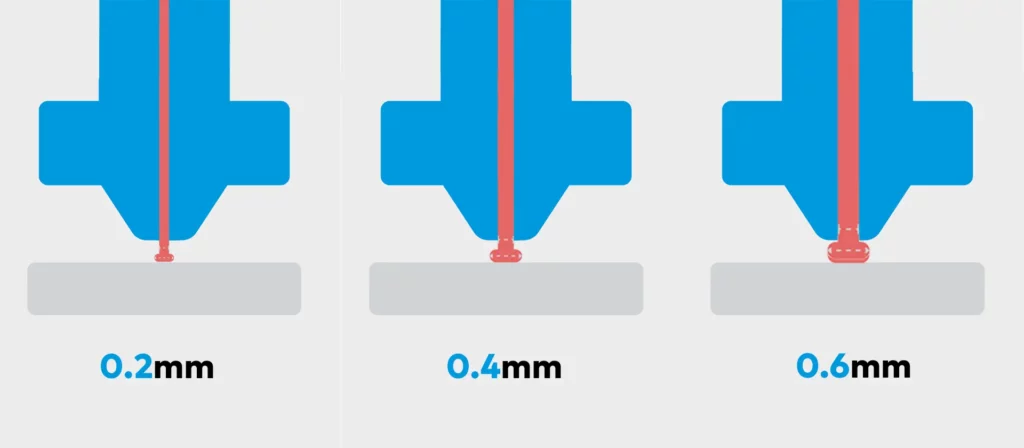

Nozzle Diameters

The diameter of the nozzle you use will determine the thickness of the filament you extrude. This in turn will affect the accuracy and precision of the printed part. Choosing a 3D printer nozzle diameter will always be a choice between speed and precision, but there are some variations that are widely considered to be the sweet spot.

> 0.4mm Nozzles

3D printer nozzles with a wider diameter than 0.4mm are on the bigger side of the nozzle diameter spectrum. While the details and the precision you get won’t be as good as what you would get with a smaller nozzle, they still have redeeming qualities.

These 3D printer nozzles will save you a considerable amount of time by allowing you to print at much higher speeds. They lower the chances of your print failing because of a nozzle-related problem as they are not prone to clogging as much as the smaller ones.

If you are experiencing clogging with your own personal 3D printer: How to Fix Clogged Nozzle

0.4mm Nozzles

0.4mm is widely considered to be the sweet spot when it comes to 3D printer nozzle diameters. The extrusion width won’t be as thick as it would be with the nozzles with wider diameters, so you will be able to get sharper details. The printing speed also won’t be as astronomically high as it would be with the smaller nozzle sizes.

While 0.4mm nozzles have been the workhorse of the 3D printing world for a while now, their use has come into question recently. With new developments in 3D printing software, getting the same precision you get with a 0.4mm nozzle using a 0.6mm nozzle is entirely possible.

< 0.4mm Nozzles

And finally, we have nozzles that have a diameter smaller than 0.4mm. The details, the quality of overhangs, and the precision you get with these 3D printer nozzles will be like nothing else on the market. The support that you print using these nozzles will also be much easier to remove. For parts that require extreme precision, these nozzles will be the best choice.

Their downside is the print times. As you can probably guess when the filament that is extruded through the nozzle gets thinner, it will take longer for prints to get finished. Also, it is recommended that you keep your layer height around %80 of your nozzle’s diameter. So, using a smaller nozzle will also force your hand into printing with a lower layer height, increasing the print times even more. These nozzles are only viable if you can sacrifice time for better details.

Need advice on reducing print times? Read: How to Get Faster Prints

Nozzle Sizes

Different nozzle sizes come with entirely different extrusion systems. So you won’t really need to know the difference between them if you are buying a new nozzle. You will have to go with that ever suits your current extrusion system but we will explain the difference between them anyway.

Standard

Most 3D printing setups work with your standard nozzles. They will be around 12-13mm long. The smaller size means it gets hot and cold much quicker compared to other nozzle types on the market. They are reliable and as basic as it gets.

Volcano

Volcano nozzles are made for a different extrusion system than your standard 12-13mm nozzle. They are usually around 21mm long and even have Super Volcano counterparts that can go up to 50mm. They work with a lighter heating system which means systems that can use a volcano nozzle can print at higher speeds. They also extrude much more filament than the standard ones.

Conclusion

When you have this many choices, picking a 3D printer nozzle will seem complicated. But when you get down to it, you won’t need a special nozzle to print most items you want to print. You will get a pretty decent performance with a 0.4mm brass nozzle and will be able to print most things you want. But if you have extra cash to spend and want to upgrade your setup, you can try the alternatives and which one suits your setup and prints the best.