Developments in 3D Printing That Could Change the Industry

One of our favorite things about 3D printing is the constant innovation that this community breeds. Whether it is the open-source culture that was cultivated in additive manufacturing communities or the relatively short lifespan of the technology, 3D printing is getting better and better every year and it is not even close to reaching its full potential yet.

The optimism that surrounds the talk about the future of 3D printing can sometimes reach the levels of a futuristic pipedream, but that doesn’t mean we won’t see amazing innovations in the industry in the near future. With major developments on the way, 3D printing has the potential to change the concept of manufacturing as we know it.

Better Recycled Filaments

Sustainability is a hot-button issue nowadays. People are becoming more mindful of their consumption habits and the effect they have on our planet. And this anxiety is not for nothing considering how the negative impact of our carbon footprint is starting to show more blatantly every year.

While some people believe real change can be made on an individual level by changing the products we buy and preferring sustainable brands, in truth, most of the carbon dioxide emission is caused by countries and individual cooperations with outstanding manufacturing outputs, who produce without caring about the impact they have on the planet. If manufacturers start adopting 3D printing more in the future and the quality of recycled filaments gets better, we can see a change in the way we look at sustainable manufacturing.

There is so much wasted plastic that gets dumped into landfills, or worse, oceans, that causes tremendous damage to the environment. If there was more motivation for companies to start recycling these materials to make filaments and the consumers to buy those filaments, we could see real change.

For more on sustainability and 3D printing: Is 3D Printing Environmentally Friendly?

Right now, recycled filaments are not the best they could be. They break easily and the print you get with them doesn’t perform or look as good as you would with a normal filament. But with better recycled filaments, consumers can start trusting and using these filaments, which would motivate other companies to adopt more environmentally friendly methods of making filaments.

Improved AI Integration

There are not many verticals that will not be affected by the improvements in artificial intelligence. AI’s ability to gather data, process it, and use the information to get better results can help 3D printing in several ways.

AI, in the near future, has the potential to improve printing quality by detecting errors or inaccuracies and fixing them in the next print by adjusting settings, to help during the design process, to make it faster by suggesting changes and adjustments, or to allow for better developments on 3D printing slicers.

Not only does AI have the potential to make individual prints better, but it also has the potential to help 3D printer farm owners with the quality control process of the mass-produced parts. Mass producing with the help of 3D printers is already a popular practice but AI has the potential to streamline the process by eliminating the need for human interaction during quality control.

Fully Automated Farms

3D printing is already a very automated process. Put the digital model in, slice it and start printing. It may seem simple, but this only goes for personal use. If you are in charge of a farm, there is still a lot of work to do. Giving the print order, taking the prints out, changing the filament, cleaning, maintenance. Yes, the manufacturing process is fully automated, but the need for human involvement is still there and you still need a considerable amount of human workforce to maintain a medium-sized farm.

With fully automated farms, 3D printing has the potential to be a much more effective manufacturing method that will be adopted by businesses of all verticals. We are not only talking about the cliché of robot arms taking out prints. That is a part of automation and no doubt can be useful, but better automation can land a hand to farm owners in quality control, maintenance, and also cleaning to ensure long and consistent production hours for the farm.

For more information on 3D printer farms: How to Start and Maintain a 3D Printing Farm

There are already great automated farms out there but the need for human interference is still not at an optimal point. Automation and 3D printing will need to develop at a comparable rate for this dream to come true. The farms that exist today use articulated arms to take out the print bed and detach the print from the sheet and put it back to continue production. Improvement in the automation industry will also benefit 3D printing in the future.

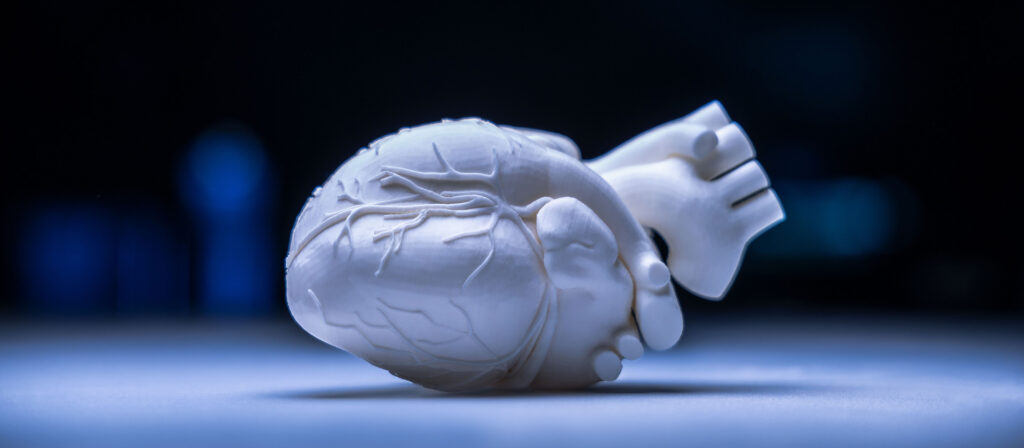

Adoption in Medicine

Medicine has always been one of the most technologically advanced services that are available to the general public and a big motivator for technological advances in history. To ensure better results in medical operations and improve patient quality of life, medical professionals depend on the help of countless tools. 3D printers, in the future, can be one of the most reliable tools for medical practitioners.

Right now, the closest milestone that additive manufacturing in medicine can reach would be personalized, 3D-printed drugs. Personalized drugs are already making huge way when it comes to mapping out people’s genomes and making drugs specific to individuals’ genes and 3D printing can make the process much easier. The potential of 3D printing truly has no limit. Until we are literally 3D printing useable organs, printing technology can improve and aid medicine in innovation.

The utilization of additive manufacturing right now includes affordable prosthetics, dental implants, and preoperational planning right now but the future of 3D printing in medicine is looking brighter by the day. With future developments, we will be able to see the full potential of this technology in medical practices.

A Surge in Home Use

One of the key things that can put 3D printing into the mainstream culture would probably be an increase in households that have their own 3D printer. 3D printers are already very important for the DIY community and the benefits of having a desktop 3D printer at home are known to a lot of people in the community. But if the convenience of 3D printers in home life were to be discovered by the general public, it would no doubt carry the industry to the next level.

Additive manufacturing is already a nearly 14-billion-dollar industry. So, there is no shortage of money in the industry per se, but the added profits and investments in a growing industry will allow 3D printing to be more experimental and braver with research & development, which in turn can lead to new developments and faster innovations.

Considering 3D printing is a fast-paced, fluid industry, there is no way of telling what extra R&D budgets and skyrocketing research and innovation would make the industry look like. Time will tell.

Conclusion

The whole 3D printing community is in unanimous agreement when it comes to the potential of additive manufacturing. We all know it is only going to keep getting better and better until it reaches its full potential if it ever does. These milestones that 3D printing reaches along the way to becoming inarguably the most reliable and effective manufacturing method there is will only make the innovations and improvements faster.