How NFCs Can Help 3D Printing

NFC is one of those technologies that is so simple and useful that you can’t be surprised how prevalent it became in such a short time period. It is already in our lives one way or another and makes some of the daily transactions much quicker. It is a foolproof system that you can wrap your head around immediately.

Like it did in so many other industries, NFCs have now found their way into the wider additive manufacturing world. Its uses are relatively limited at this point, but the convenience it provides now makes you wonder if it has a bigger future for 3D printer users.

What is NFC?

NFC, which stands for near-field communication, is a set of protocols that enable data transfer between two devices. The concept itself is fairly basic and is based on simple radio-frequency identification technology. Its simplicity and convenience lent itself to many uses in daily life and it is progressively getting more popular.

NFC at its simplest revolves around a passive tag that contains data and a reader that both powers the tag wirelessly and reads the information on it. These tags are generally pretty cheap and reusable as you can rewrite the information on them.

The amount of information a tag can hold will depend entirely on its type with Type 1 NFC tags holding around 1 kilobyte of data while the more advanced ones like Type 5 hold nearly 32 kilobytes. At first glance, these numbers might seem a little small, but there are countless ways of using them if you get creative with it.

How We Use NFCs in 3D Printing

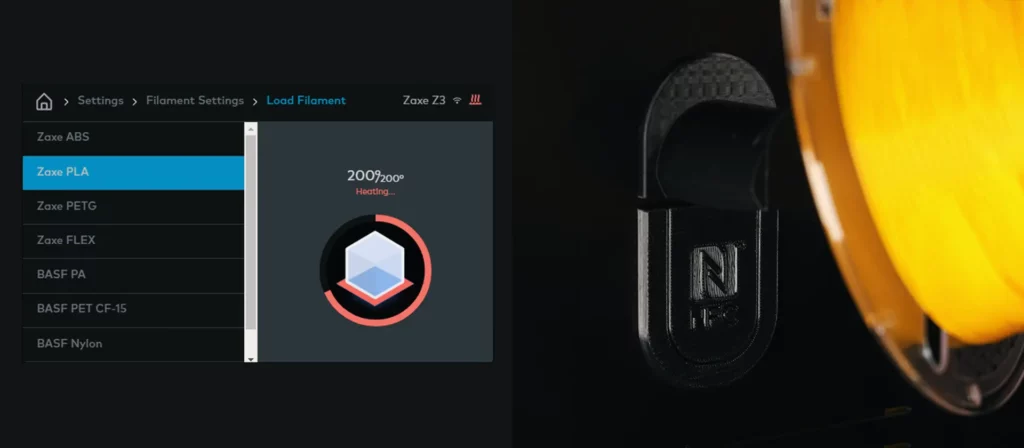

The best example of NFCs being used in 3D printing right now is the convenience it provides when attached to filament spools. With help of an NFC, a 3D printer can read the tag and acquire highly useful information to make the process much easier for the customers. Some of the things that we write on the NFC tags in our filament spools are;

Material Type

One of the most important pieces of information that can be put on NFC is of course the type of the material. In a lot of 3D printers, including ours, the filament spool holder is in the back of the machine. So, leaning over and looking is not necessarily the most comfortable if your device is placed in a tight or high place. Keeping track of what type of filament is installed in which device is much easier for people who have multiple 3D printers thanks to this feature.

Filament Color

It is good to take the color of your filament into consideration as different coloring agents will affect how materials behave in different circumstances. Detecting the color of the filament is not that big of a deal considering you can do it yourself by just taking a glance at the extruder or behind the device. But when your device reads the NFC tag on the spool and recognized the color, it will adjust the printing settings according to not only to filament type but also the color which will help you achieve better results with minimal effort.

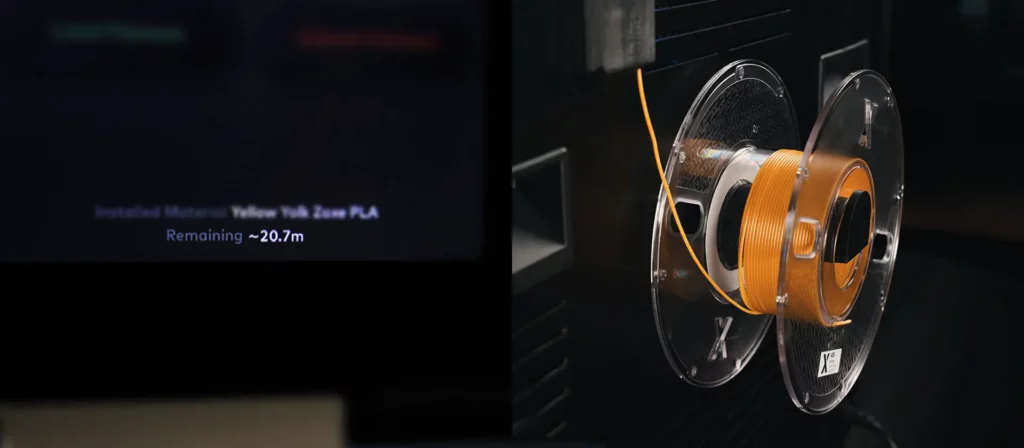

How Much Filament is Left

The information on the NFC tags is generally rewritable. This allows the users to reuse them when needed but also creates opportunities for more clever uses. We use this ability to keep a track of how much filament is left on the spools. Every time you use a spool of filament for a print, the amount you use is subtracted from the tag. This way your device will always know if the spool that is installed in the 3D printer has enough filament to finish your next print or not. NFC tags eliminate guesswork and save you time on prints that are doomed to fail because of the lack of filament.

Final Thoughts

NFC’s biggest contribution to 3D printing is admittedly very modest right now. But even a seemingly small utilization can make getting into 3D printing much easier for beginners and provide much-needed convenience for experienced users who operate more than one device. It probably won’t change the industry but it would be interesting to see what more this technology can do for additive manufacturing.