FDM vs SLA: Which One is the Better Option for You?

In public discussion, 3D printing is often referred to as a single entity that seemingly doesn’t have different subcategories. But actually, 3D printing can be considered as more of an umbrella term that can be used to describe several different manufacturing technologies.

The fundamental difference between other manufacturing methods and additive manufacturing is a 3D printer uses materials to turn digital designs into 3D models from scratch without needing the help of any other machine.

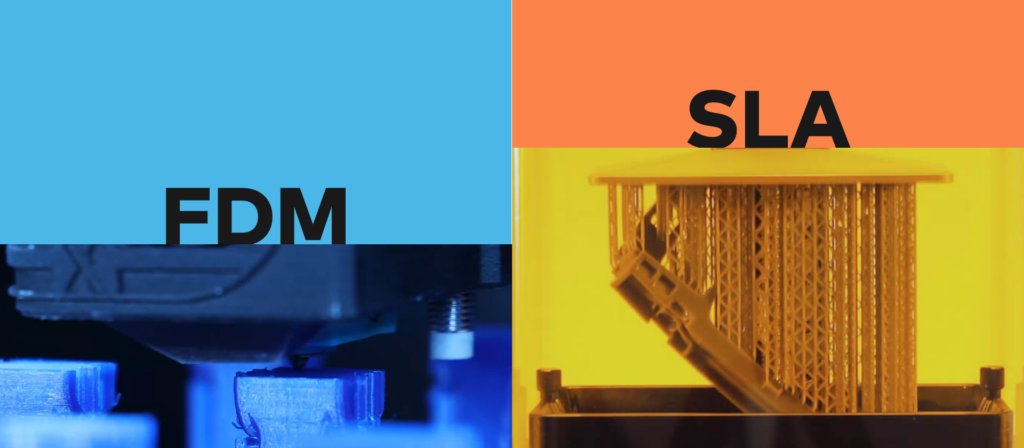

FDM and SLA 3D printers are usually considered to be similar because the service they provide is. While they use different methods to achieve similar results, there are still important distinctions between 3D printing technologies that the buyers should be aware of.

What are FDM and SLA?

There are currently two dominant technologies in 3D printing that is familiar to most people who are interested in additive manufacturing. While FDM and SLA are comparable in some aspects, they are fundamentally different technologies that use different methods to print 3D models.

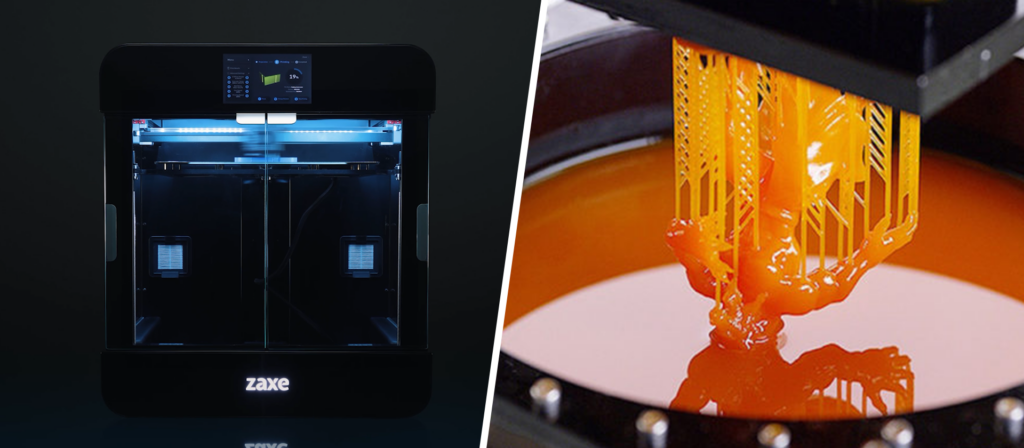

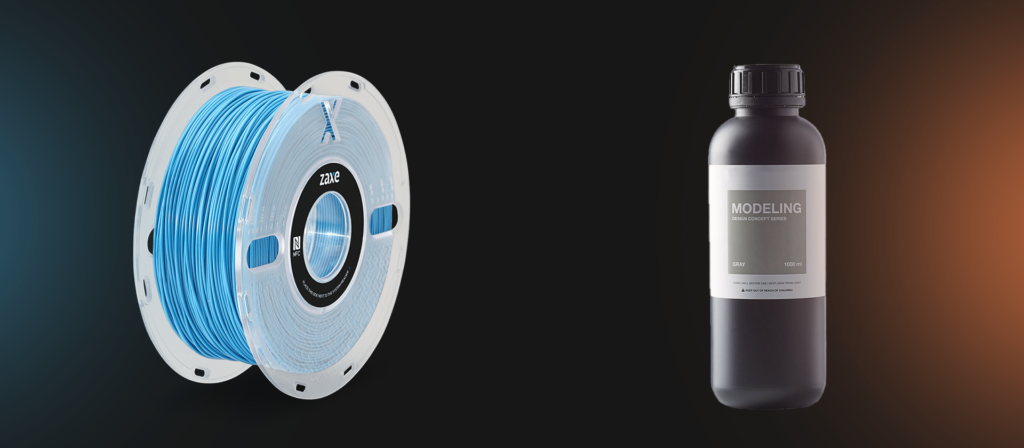

FDM technology, which stands for fused deposition modeling, uses an extruder to print thousands and thousands of layers on top of each other to manufacture a 3D model. The printers use materials that are called filaments that get melted in your 3D printer’s hot end, and get extruded as thin layers.

SLA, which stands for stereolithography, is a different 3D printing technology that utilizes a laser or projector to cure liquid material and turn it into a solid model. Instead of using a thin thread of filament like FDM 3D printers, SLA uses liquid resin as material.

Comparisons

When you have to choose between the two, their respective capabilities will be deciding factor. Both FDM and SLA 3D printers excel in different fields and provide subpar results in others. The strength and weaknesses that will determine your decision will mostly be based on what you are going to use the 3D printer for. Some of the factors that should dictate your decision will be;

Speed

The speed of the printing process might depend on the capabilities of your 3D printer more than the characteristics of the technology. Both methods can give pretty fast results but in general, FDM will be faster than SLA. The lasers that SLA printers use have a very small surface, so it takes them much longer to cure each layer.

You will have much more freedom on the length of your printing process if you have an FDM 3D printer. You can adjust infill density, support angles, and layer height to make the process much faster. You will have the option to compromise on detail for more speed and get the quickest results. That’s why if you are looking for a 3D printer that will give you the best results in rapid prototyping, you should probably go with an FDM device.

Precision

Under the right conditions, both technologies can make models of extremely precise details. But a standard SLA 3D printer will be able to print much better details than a standard FDM 3D printer. An SLA printer can give you a resolution of 25 microns with ease and the models will have a silky smooth finish to top it off.

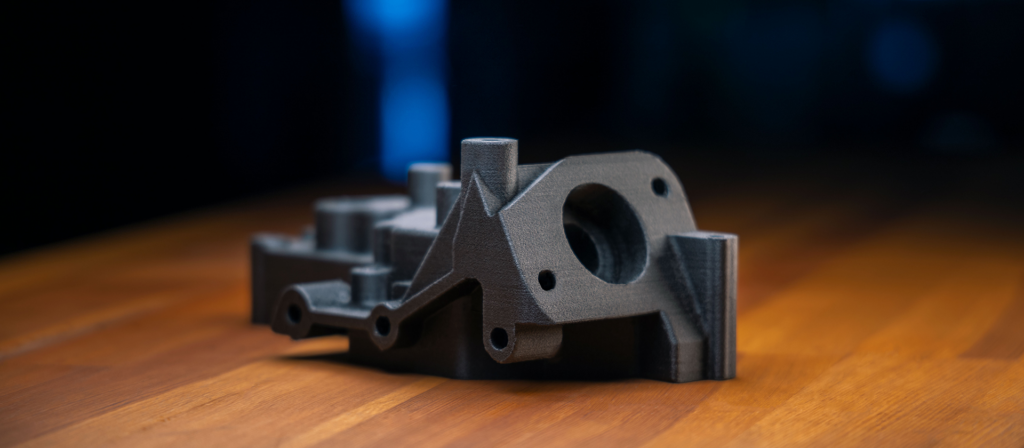

FDM 3D printer also can achieve fine details and complex geometries with great dimensional accuracy but the finish of the end product will have thin, horizontal lines. These lines can be dealt with in post-processing using a sander but you are unlikely to get the same finish you would with an SLA 3D printer.

Durability

When we say durability, we are talking about the durability of the prints, not the devices. The resins SLA 3D printers use were not designed to have a physical function. While they are very efficient at making models that have smooth finishes and amazing details, the physical properties of the printed models are not exactly great. SLA-printed parts will degrade and break much quicker than a model printed with an FDM 3D printer, so they are not optimal for end-use parts.

The strength of the models that were printed with an FDM machine comes from the great material options you are going to have. Depending on the property your product needs, whether it’s heat resistance, shock absorption, UV resistance, or rigidity, you can just pick the best filament for the job and start printing.

If you want to increase the durability of your FDM printed parts: How to Make 3D Printed Parts More Durable and Stronger

Materials

One of the main things that make FDM 3D printing so flexible is the countless material options you will have. Even a run-of-the-mill FDM 3D printer can print using materials like ABS, PLA, PETG, ASA. For an SLA 3D printer, on the other hand, your options will be severely limited to choosing between some certain physical properties like toughness or flexibility.

SLA is a little bit more limited when it comes to the materials you can print with. You will have standard options like clear resin, flexible resin, or tough resin, but your choices will be very limited when compared to the wide selection of filaments you can use with an FDM 3D printer.

Read more: FILAMENTS 101

Cost

Both 3D printer-wise and material-wise, FDM is a much more budget-friendly method of additive manufacturing than SLA. Different resin types are usually much more expensive than standard filament types and the price of an SLA 3D printer is higher than that of an FDM 3D printer of the same caliber.

There are great, high-quality filaments on the market that have very reasonable prices but the same can’t be said about SLA 3D printers. If you want a high-quality resin, you will have to pay much more than you would for a high-quality filament.

If you want to spend less and print more: 3D Printing on a Budget: How to Cut Costs While Printing

Health and Safety

Operating a 3D printer is much safer than most other machines used in manufacturing as 3D printers do most of the work without needing your input. So, as long as you let the machine do the work there is a very low chance of a work accident happening.

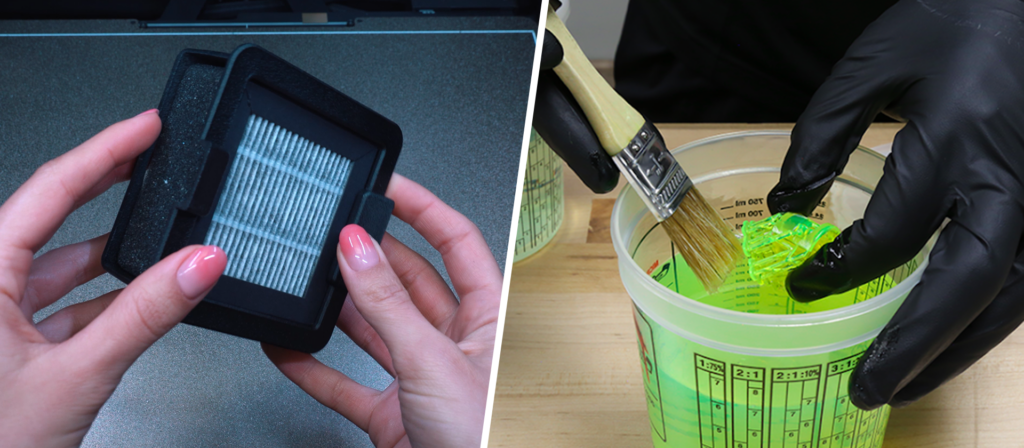

What makes SLA slightly more dangerous than FDM is the material used in the printing process. The resin used in SLA devices is notorious for being highly toxic. You will need to wear protective gloves while handling SLA printer resin and prolonged exposure to the material can cause irritations in the lungs.

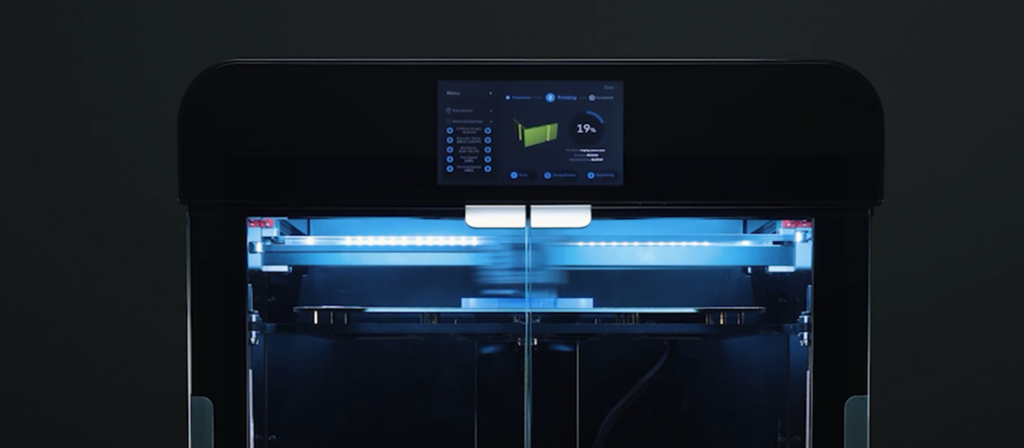

FDM devices also release the particles of the filament you are printing with and it is not like breathing in ABS all day is good for your health but with the help of filters and enclosures, the amount of plastic that is released in the environment can be reduced significantly.

Which one is the Better Fit for You?

It is hard to determine a superior method among these too. You will have to approach this subject with more nuanced than that. Depending on the specific needs of your business and the budget you have, the best 3D printing method for you will change.

If there is one thing that SLA 3D printing excels at, it would undeniably be precision, dimensional accuracy, and aesthetics. SLA printers are amazing at manufacturing models with silky smooth finishes that don’t have the visible layers that FDM printed models have. The tradeoff is the price for individual prints and the device itself.

FDM on the other hand excels at producing functional models at a very fast pace. Rapid prototyping and mass production of durable end-use parts are only some of the benefits that FDM 3D printing offers. Each business’s needs are different, so while there is no clear winner here, you will probably have an idea of what might be the better option for you by now.