3D Printing on a Budget: How to Cut Costs While Printing

We always go on and on about how 3D printing is one of the most affordable manufacturing methods and how it can help you reduce your business expenses in many different ways. But there are still ways to make it even more affordable.

People can often be financially frivolous while using their 3D printers because they think the money they spent on it is already pretty reasonable. This will probably not be a good attitude in the long run as the money you spend on 3D printing adds up.

Even if you are not frivolous with your expenses, some home users might see the need to spend less money on 3D printing to support their hobby. Different budgets make for different printing circumstances and we would like to help you reduce your monthly 3D printing cost with small adjustments in your printing habits.

How to Reduce 3D Printing Expenses

Most of these tips will revolve around reducing the amount of filament you use on individual prints and trying to keep the electricity bill down as those two are the things that people spent the most money on. It is important to keep in mind that while these tips will help you save money, you should keep a good balance between economical printing methods and print quality, especially for end-use products.

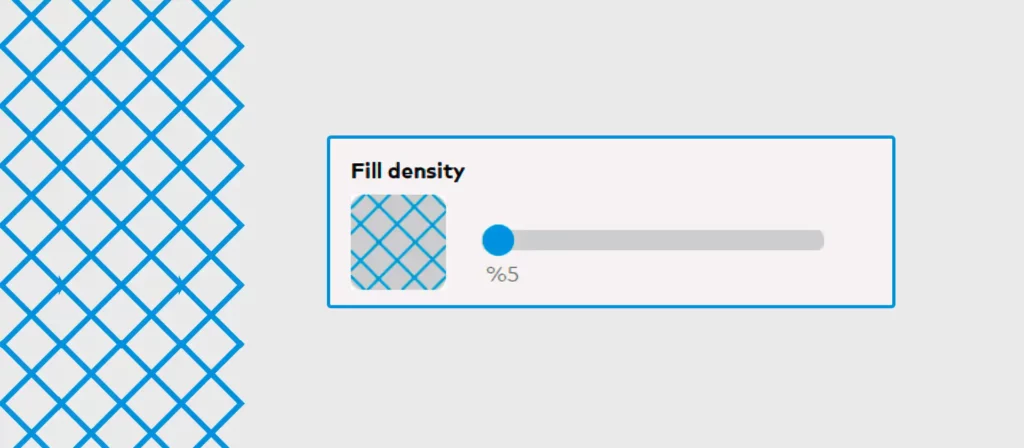

Reduce the Infill Density

Keeping the infill density to a bare minimum will help you keep the costs down in a number of ways. First of all the amount of filament, you spend on the print will decrease to a considerable degree. Secondly, your device will work for a shorter period of time which makes the device spend less electricity. While this method is one of the easiest and most obvious steps you can take to reduce your 3D printing spending, we don’t recommend this for end-use products that you might print as it will inevitably have a negative effect on the performance of the part.

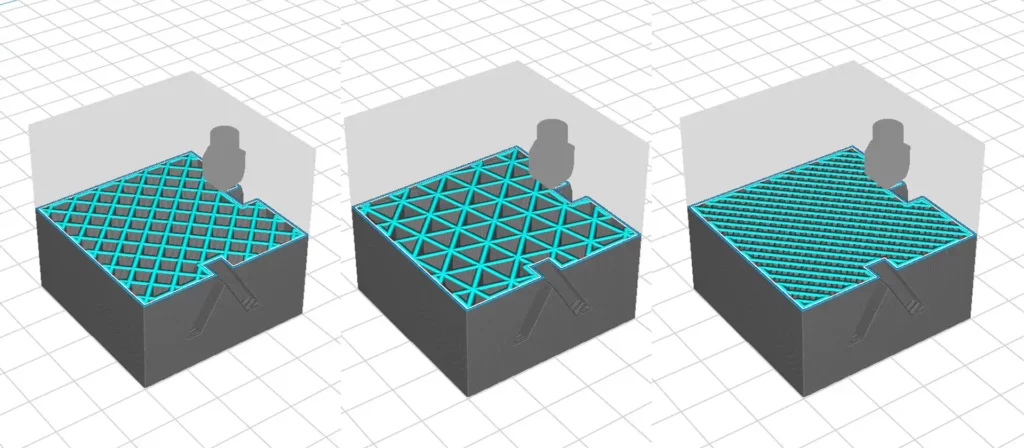

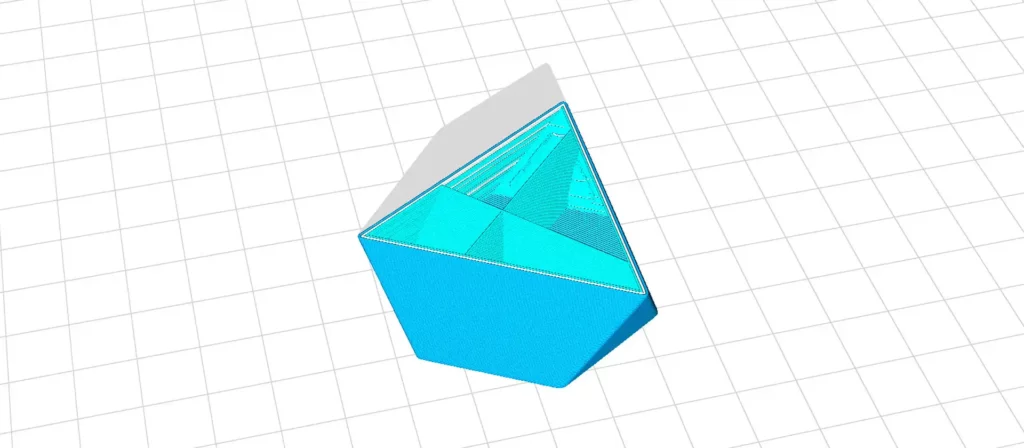

Use Budget-Friendly Infill Patterns

The pattern of the infill has the potential to reduce printing costs as much as density does. Some patterns are for end-use products and are great for parts that require durability and shock absorption. But if you are printing a model for prototyping or display purposes, there is no reason to use an infill pattern like the gyroid. The infill pattern that will give you the best bang for your buck will be the lines pattern. It reduces the amount of filament you use significantly and is pretty much the fastest infill pattern you can print with. Combined with the method above, you should be able to get much faster prints that keep the filament usage to a minimum.

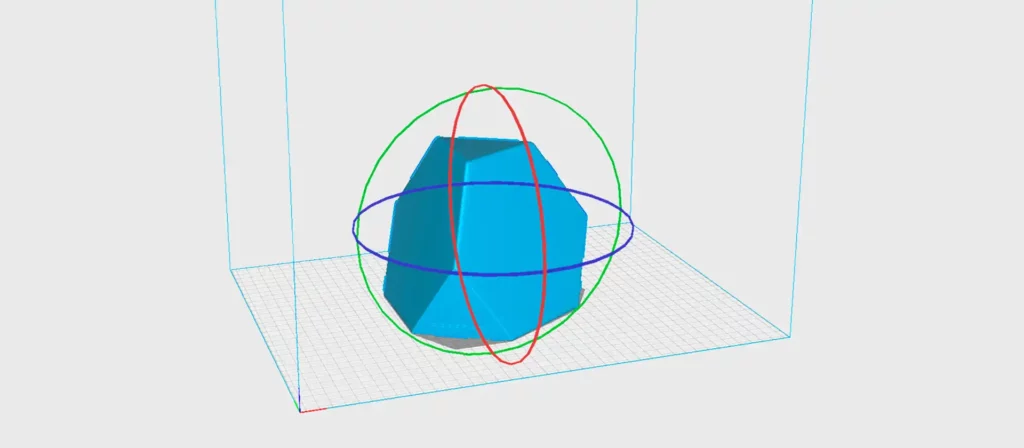

Adjust Model’s Orientation

Model orientation will also play a huge part in filament usage and print times. Not directly, but your print’s placement in relation to the print surface will determine how much support will need to be printed. Most of us place the model on the slicer in the way we would display or use it but that doesn’t have to be the case. By placing the flattest surface on the print table, you will reduce the need for support and will be able to print faster, using less filament. Try different orientations, slice your model and inspect the print times to find the best one.

Buy Your Filament in Bulk

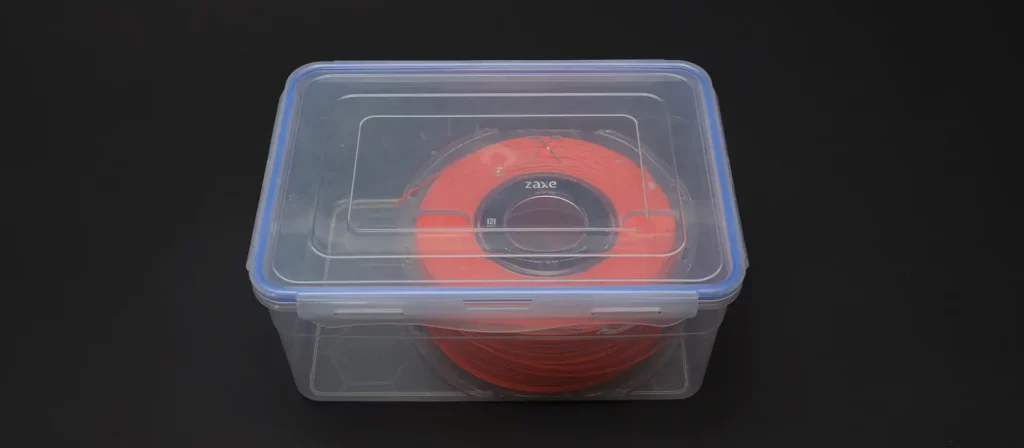

The filaments you use for 3D printing will make up a good chunk of your monthly 3D printing expenses. You already know how to spend less of it by now, but you can save even more money while buying it if you find a good deal. Most distributors and resellers will be willing to give you that good deal on your filament purchases if you buy it in bulk. The only problem is, that filaments don’t really have the longest shelf life. They tend to decrease in quality if you don’t store them in proper conditions. If you are willing to make an effort to conserve them the right way, you can spend money by buying your filament in bulk.

Learn How to Store Your Filament

Speaking of conserving filaments, putting more care into storing the materials you use for 3D printing can save you money in a number of ways. Firstly, you will get the opportunity to buy them in bulk for a good deal. Secondly, even if don’t buy them in bulk, storing the ones you have in the right conditions will decrease their chances of going bad. Most users have a couple of spools lying around their homes or workspace that they don’t bother storing. These filaments can go bad in suboptimal storing conditions and go to waste.

For more on storing filaments: How to Store Your 3D Printer Filaments Properly

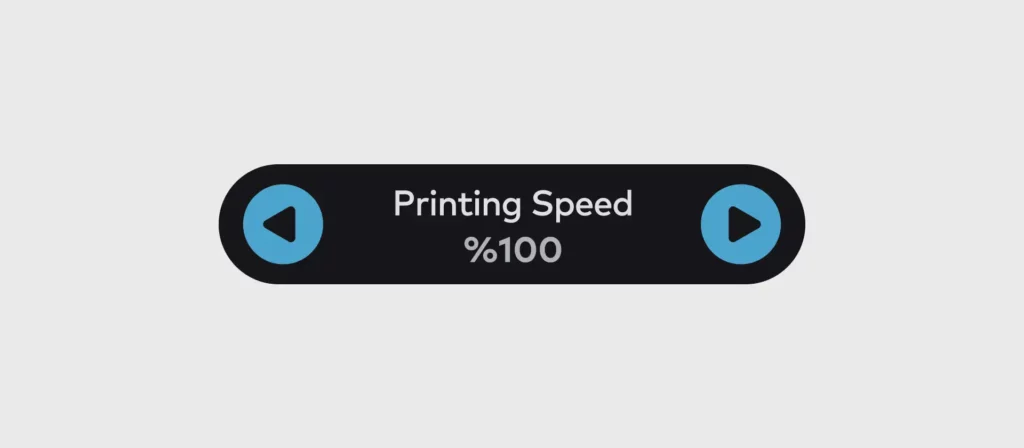

Try Increasing the Print Speed

Increasing the print speed on your device is a double-edged sword. On one hand, you are keeping the print time short, therefore keeping your device on for a shorter period of time. On the other hand, the increased speed makes the print head work much harder and faster, forcing it to spend more electricity. While you win some and lose some, printing faster will still save you a considerable amount of electricity. Especially for 3D printers that have a heated plate, which is known to be responsible for three-fifths of the energy expenditure in some models.

Be on the Lookout for Free Models

Filaments and electricity are not the only things you will need to spend money on for 3D printing. The models you acquire online to print will often come at a cost. Selling your designs online is actually a pretty reliable source of passive income for many designers but like with everything else, the money you spend on these models might add up in time. If the model is not something very specific, you might find a free alternative on one of the many .stl libraries online. We obviously don’t condone pirating designs, but there might be more than one design for a print that has the same purpose, and making effort to do more research might save you some money.

Compensate While Modelling

If you don’t rely on .stl libraries and prefer to make your own designs, there are a couple of tricks you can’t use to make your prints more budget-friendly. Most stl files you are going to find only will be designed as solid objects. The fullness of the model can later be determined through infill settings. But you can design your models in a way that eliminated the need for infill. By keeping the model as hollow as possible and intentionally leaving blank spaces in your designs, you can achieve lighter and quicker prints. Just make sure to not leave any sharp slopes that would require supports to print. That would make the design changes pointless.

If you are interested in making your own 3D models: Best CAD Software for 3D Printing That Designers Should Try

Try Recycling Old Prints and Filaments

This is not something that can be done by any 3D printer user and is only recommended for experienced makers out there. We all waste a lot of filament unintentionally because of failed prints and leftover filament on spools that are not enough for a single print. Most people just throw them out, but there is a way to turn these failed prints and leftover filaments into brand new spools of filament. With the help of one of the small filament makers that you can easily use at home, you can just make your own filament. There is actually a great CNC Kitchen video on this subject that you can watch as a guide. Keep in mind that the filament you make will probably not be nearly as good as the ones you buy at the store but through experimentation and a little experience, you can start getting good results in time.

In Conclusion

By using a combination of these tips, you can decrease the amount of money you spend on 3D printing noticeably or increase your printing output without breaking the bank. Most of these methods are not recommended for end-use products or spare parts as the quality of your prints might change after applying these solutions. But for display prints and prototypes, you will probably be fine as long as these tips don’t ruin the visual appeal of your prints.